HIVE

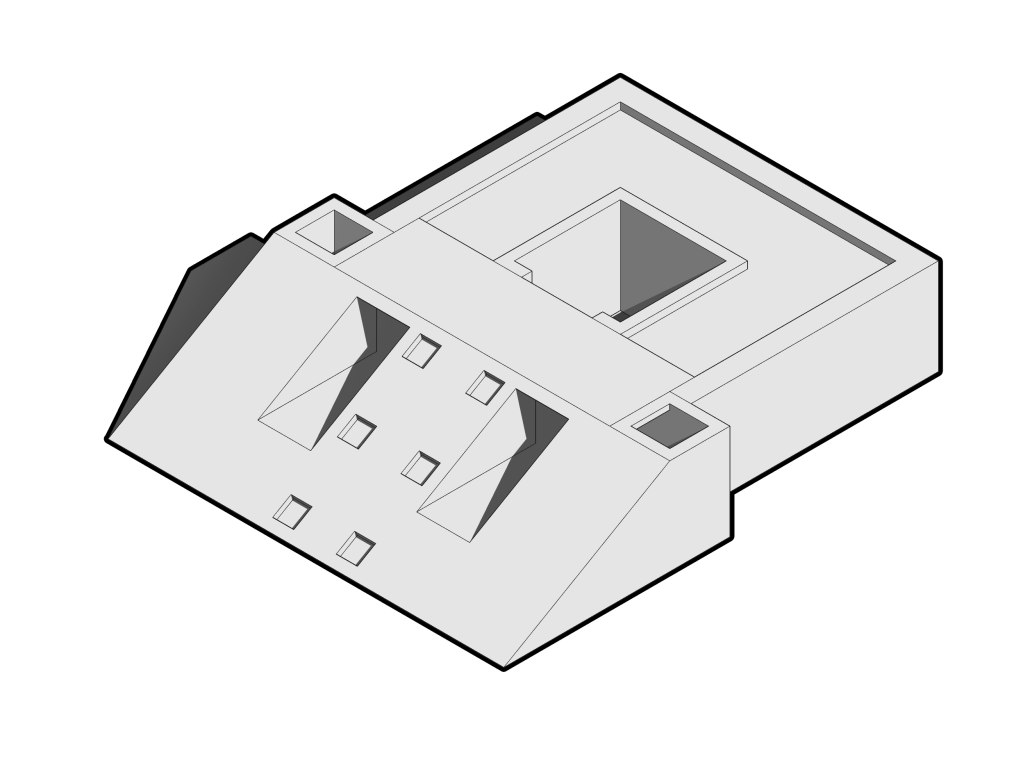

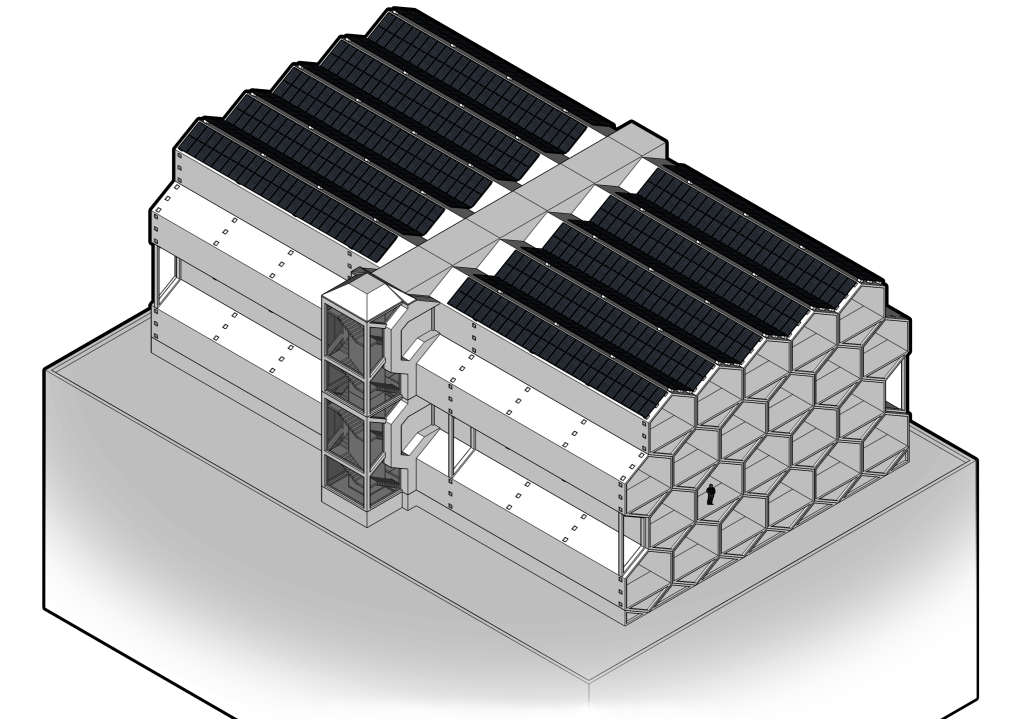

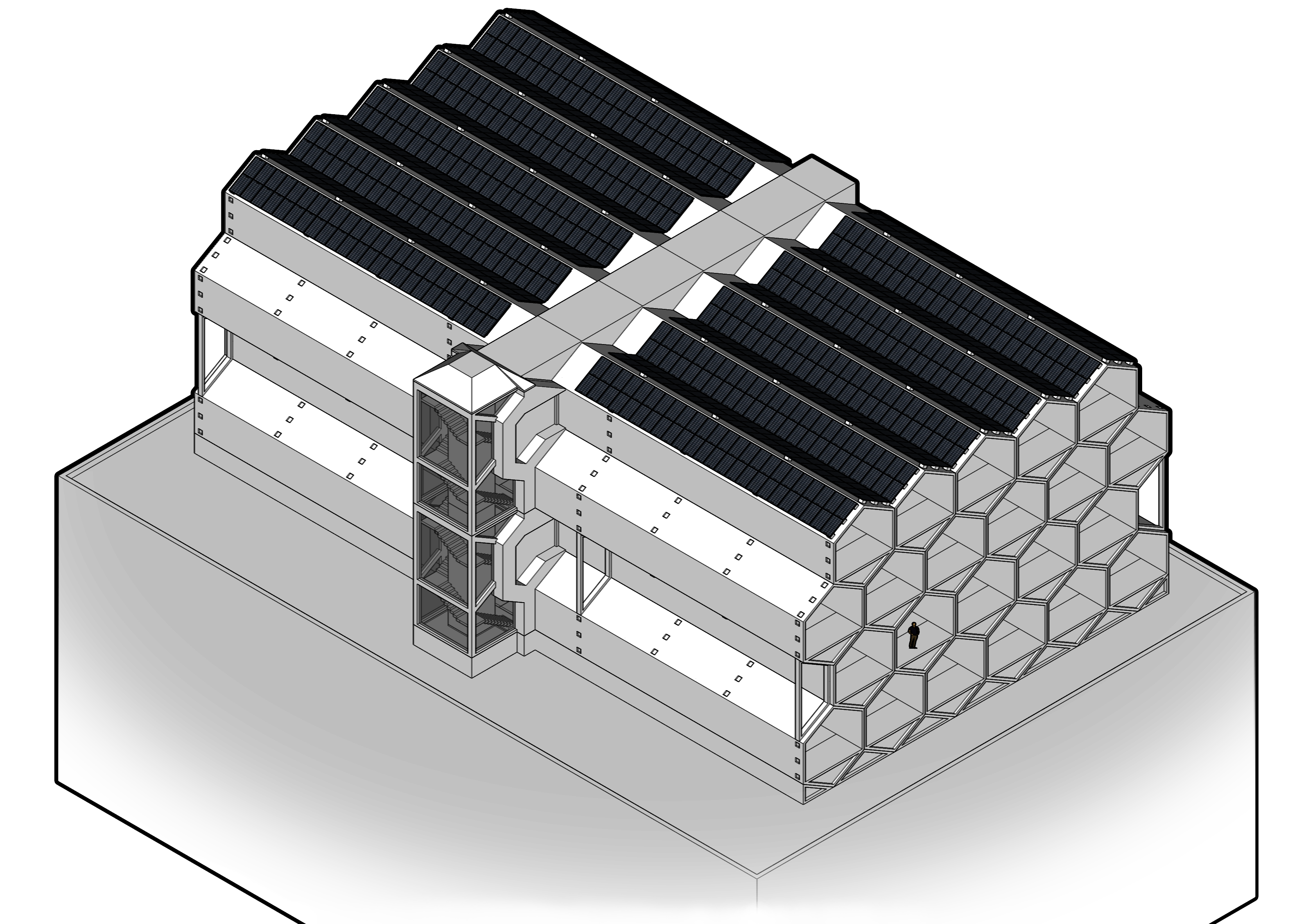

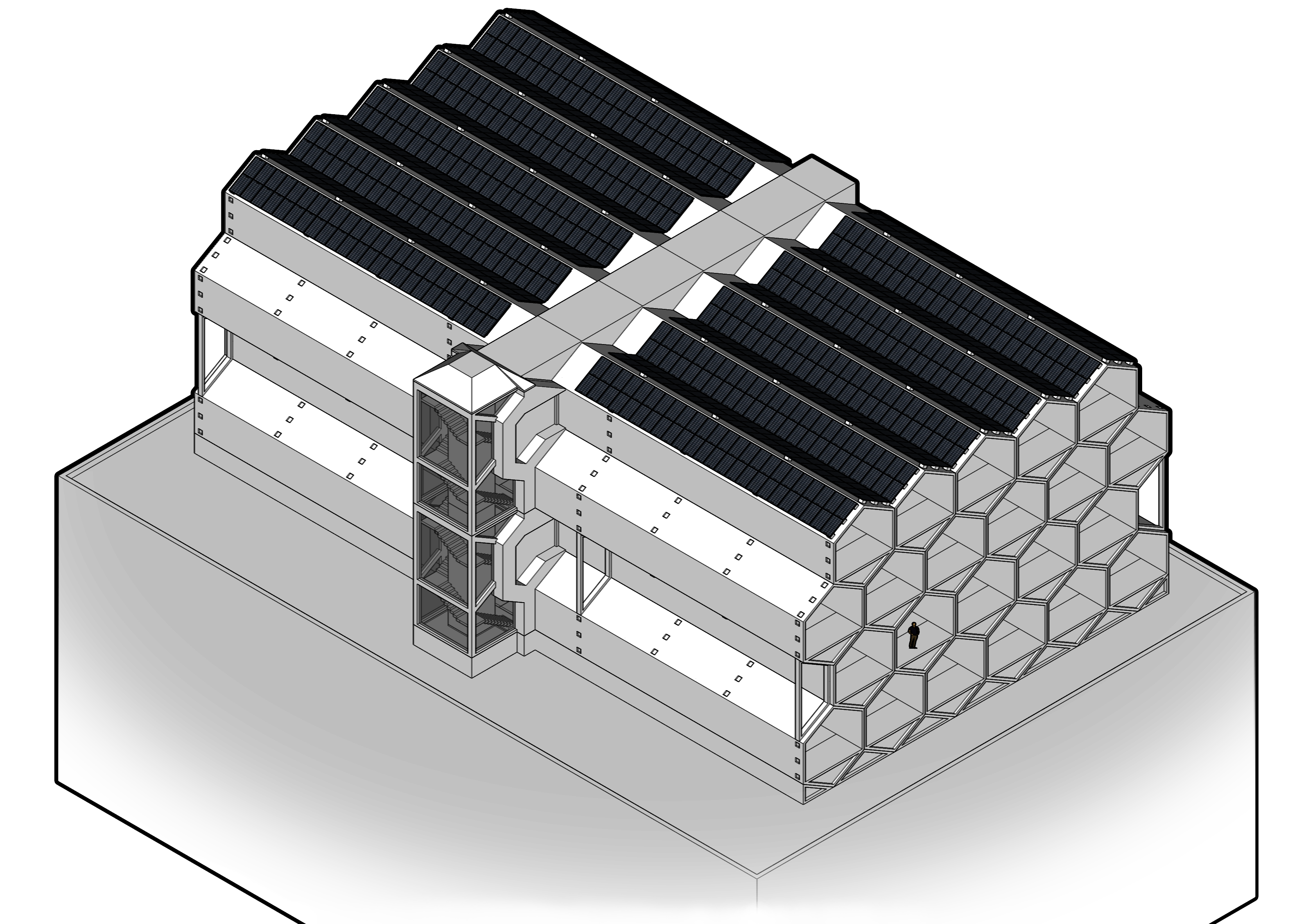

In a world where space is becoming a precious commodity, increased densification of cities will become necessary if we are to maintain a balance between Urban, Agricultural, and Natural environments. However, it is not always practical to demolish older buildings in order to construct taller ones, this is where ‘vertical extensions’ of existing buildings comes into practice. This project was the result of a design reseach course which called for new and innovative approaches to construction around the world. It specifically asked students to develop new ways to renovate and add floors to tall buildings as an alternative to complete demolision and new construction.

The addition of new floors to existing buildings is not new, patents exist from 1987 for a system to add additional height to extant structures. The need for more space will require innovative solutions to quickly and affordably meet these challenges.

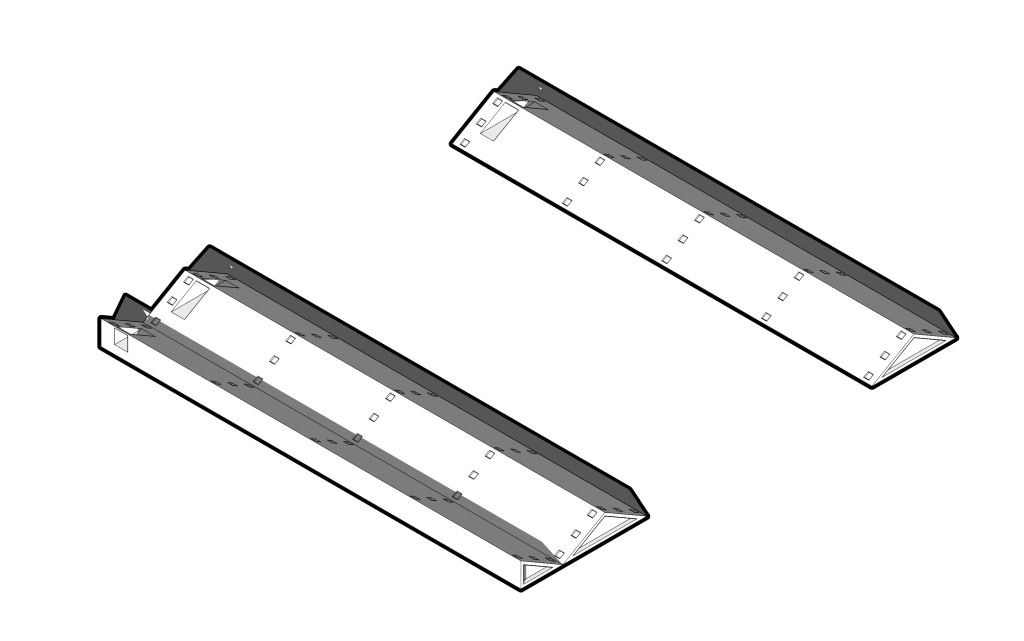

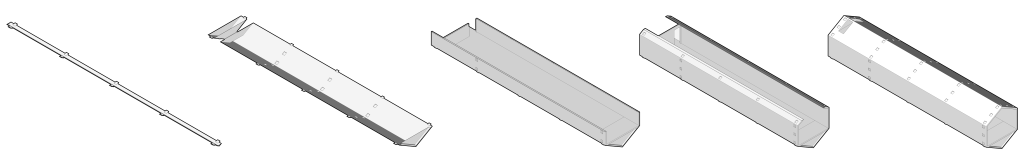

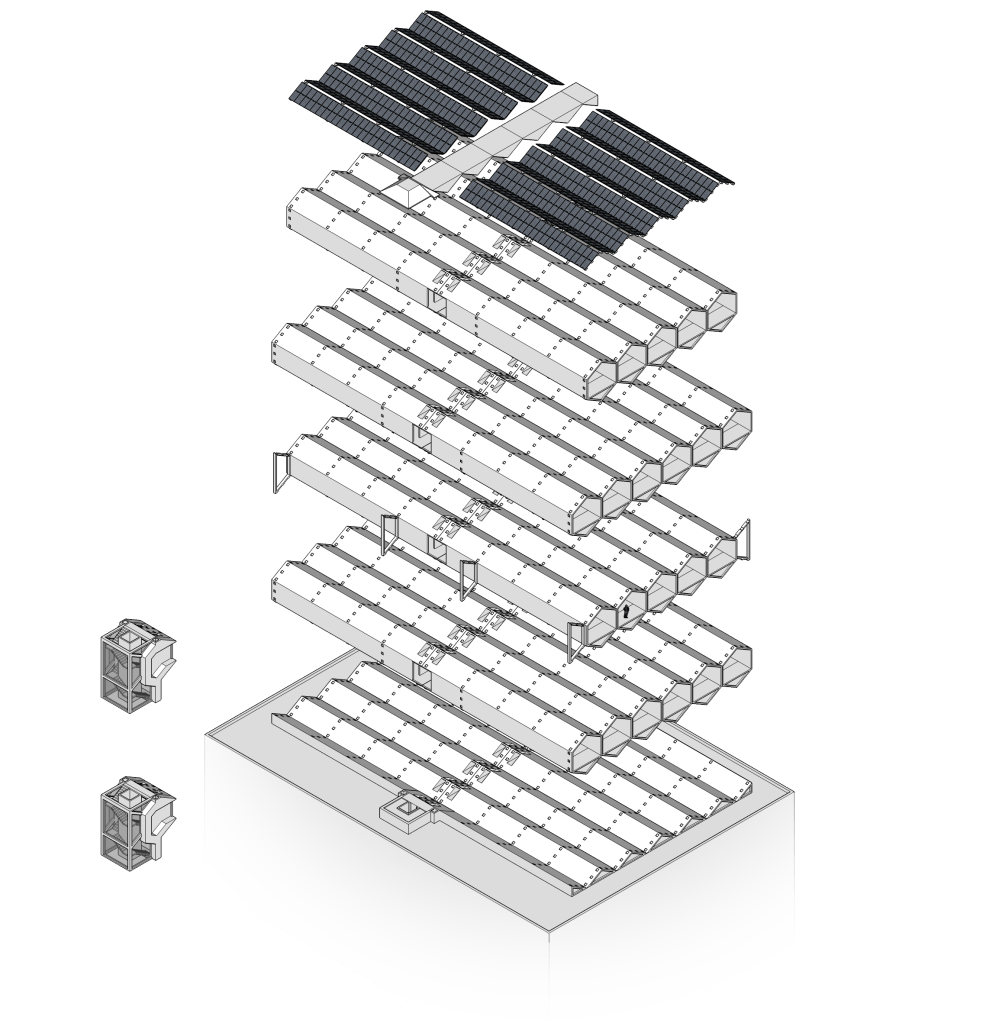

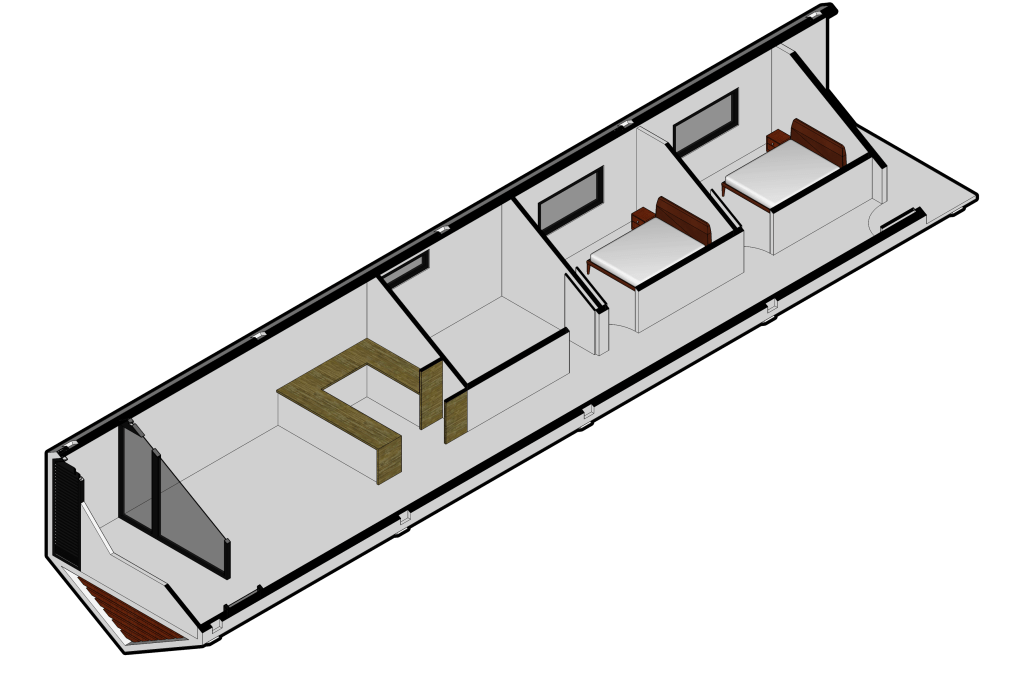

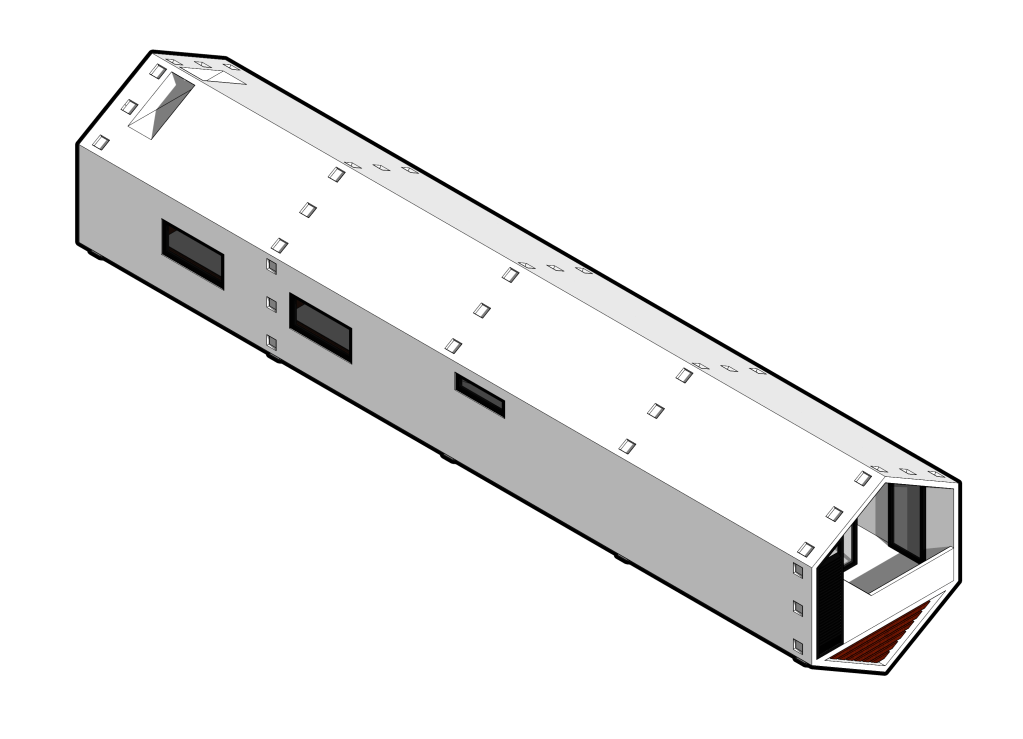

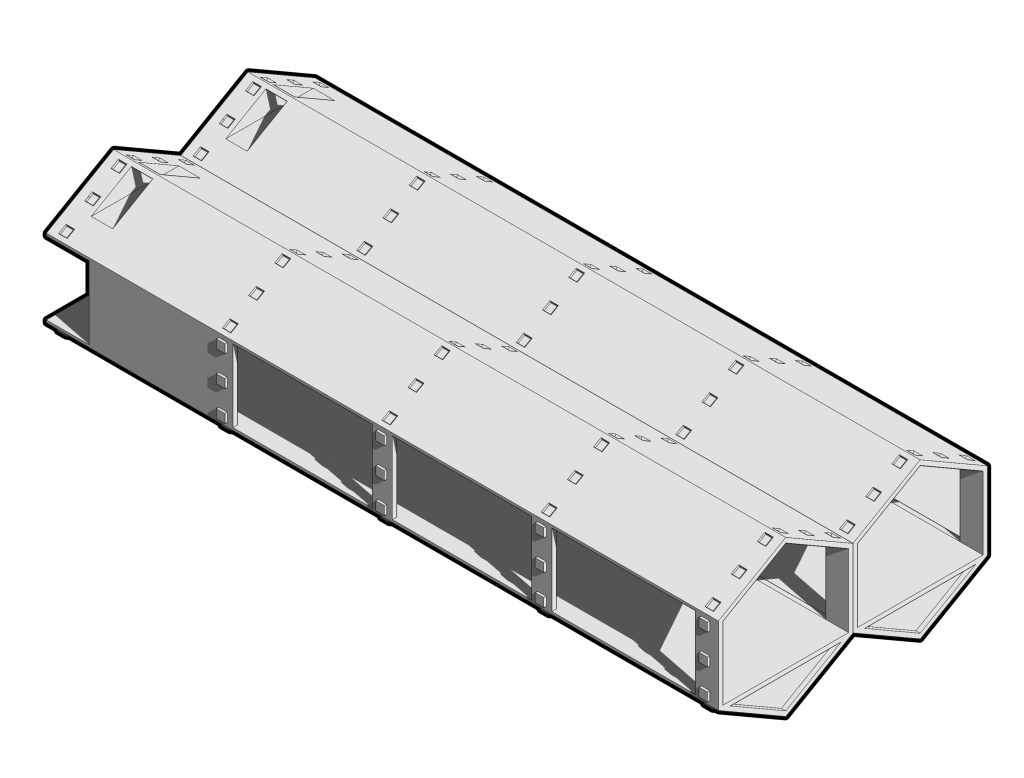

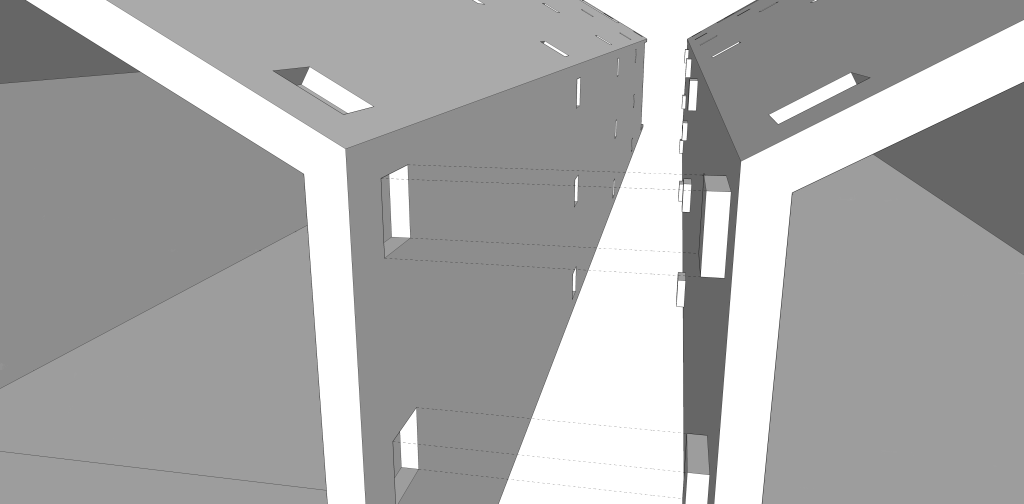

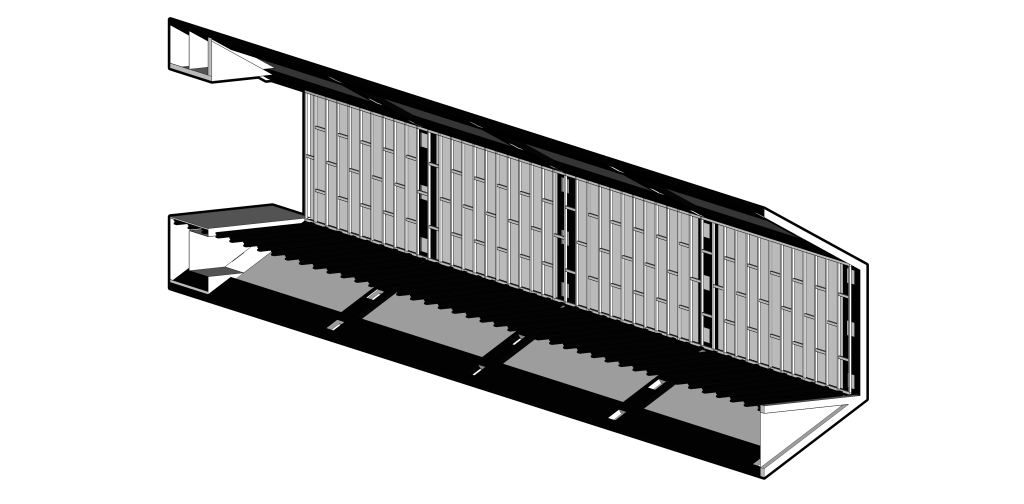

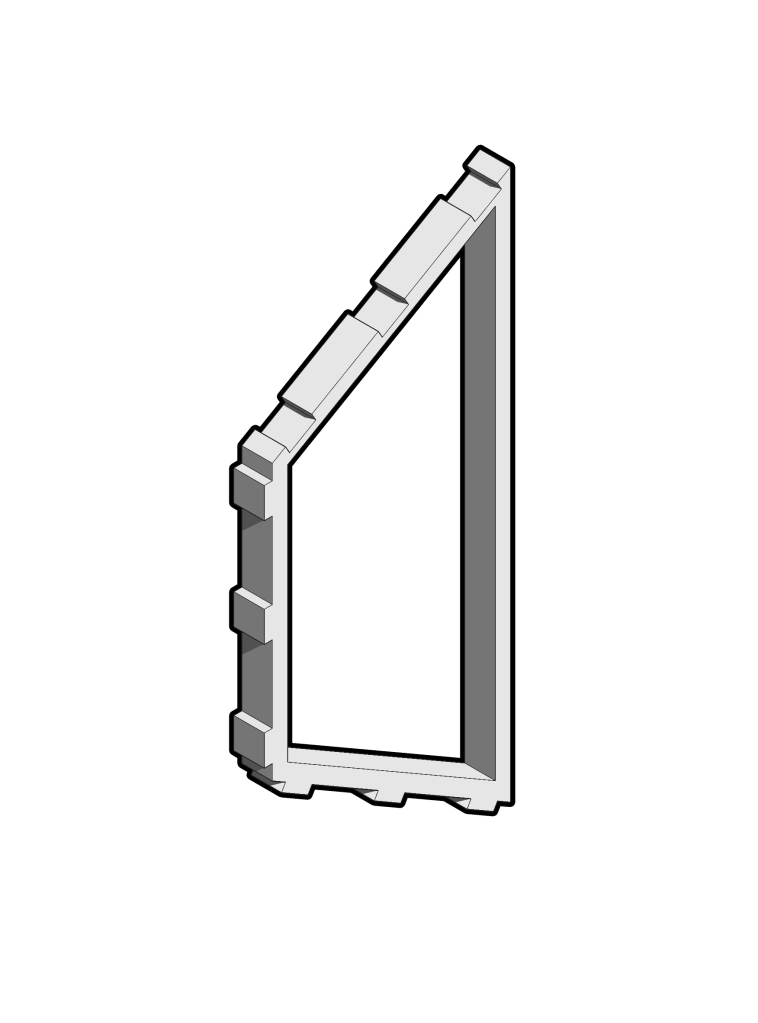

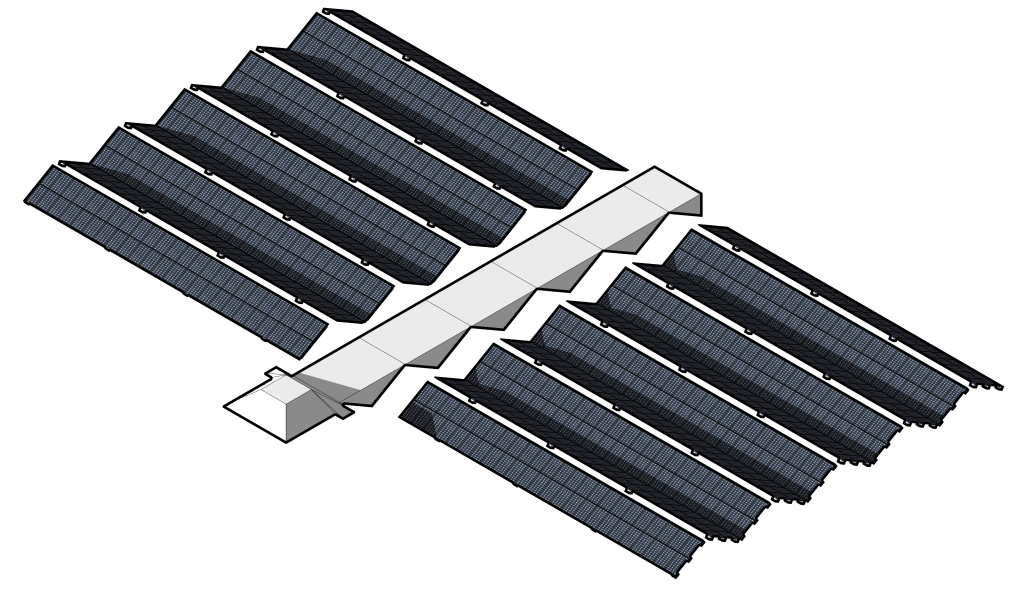

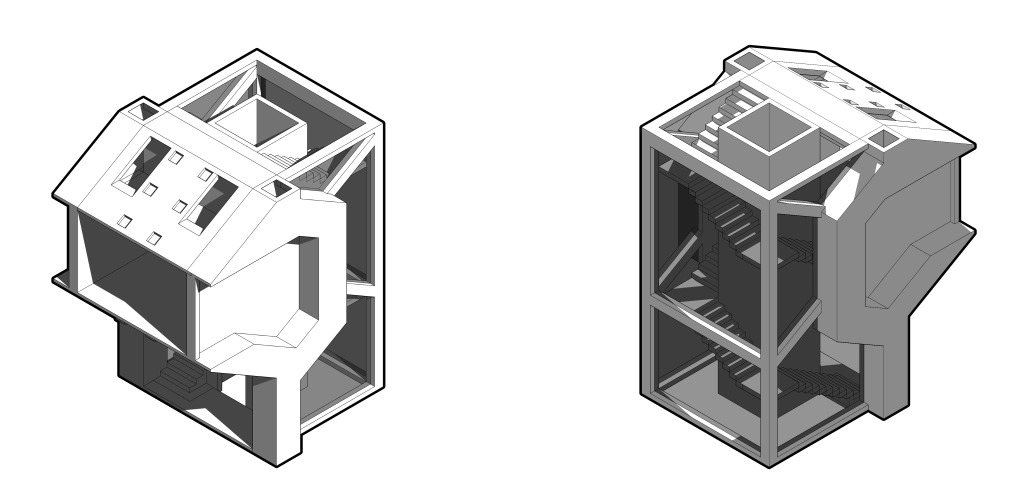

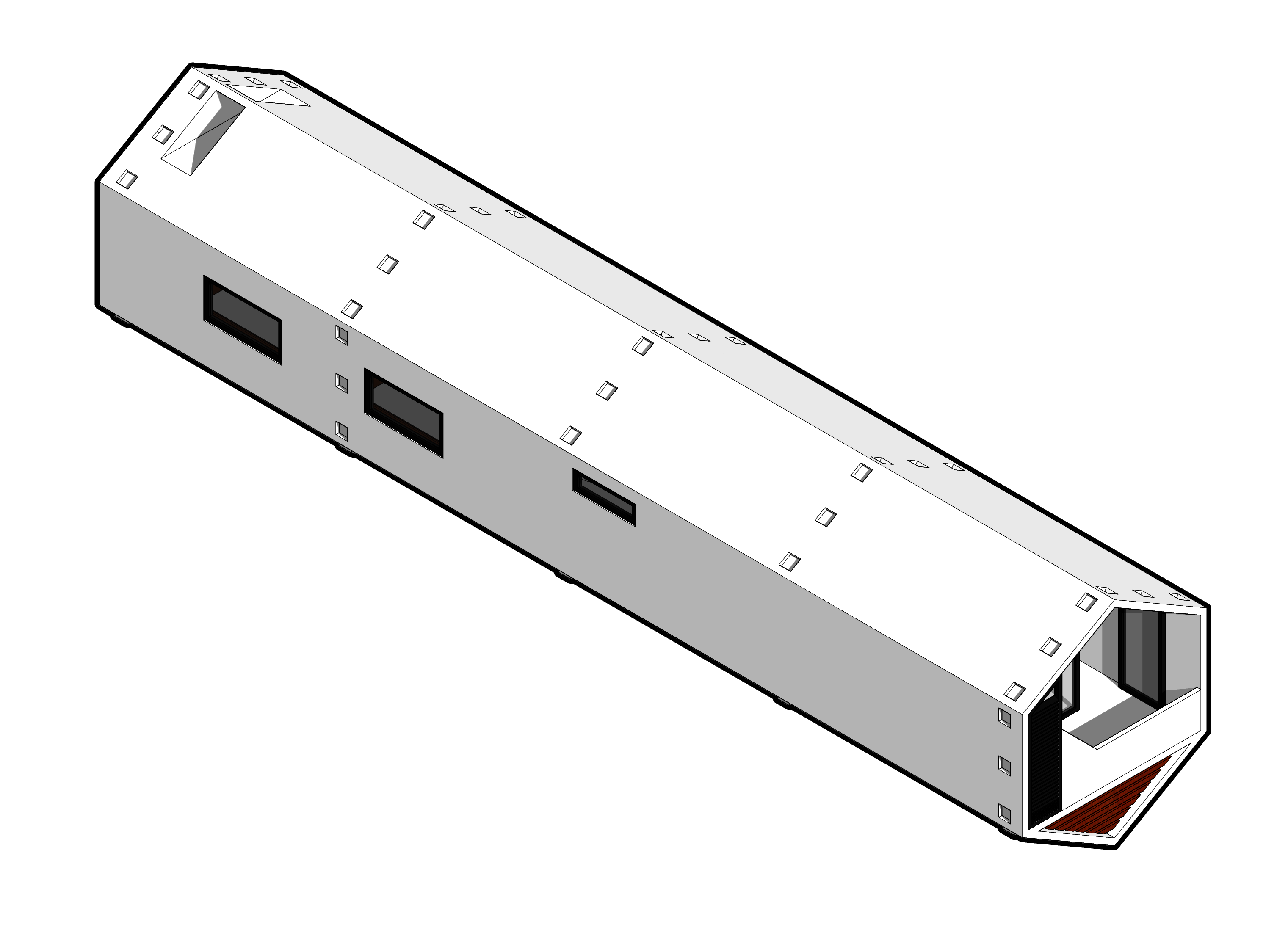

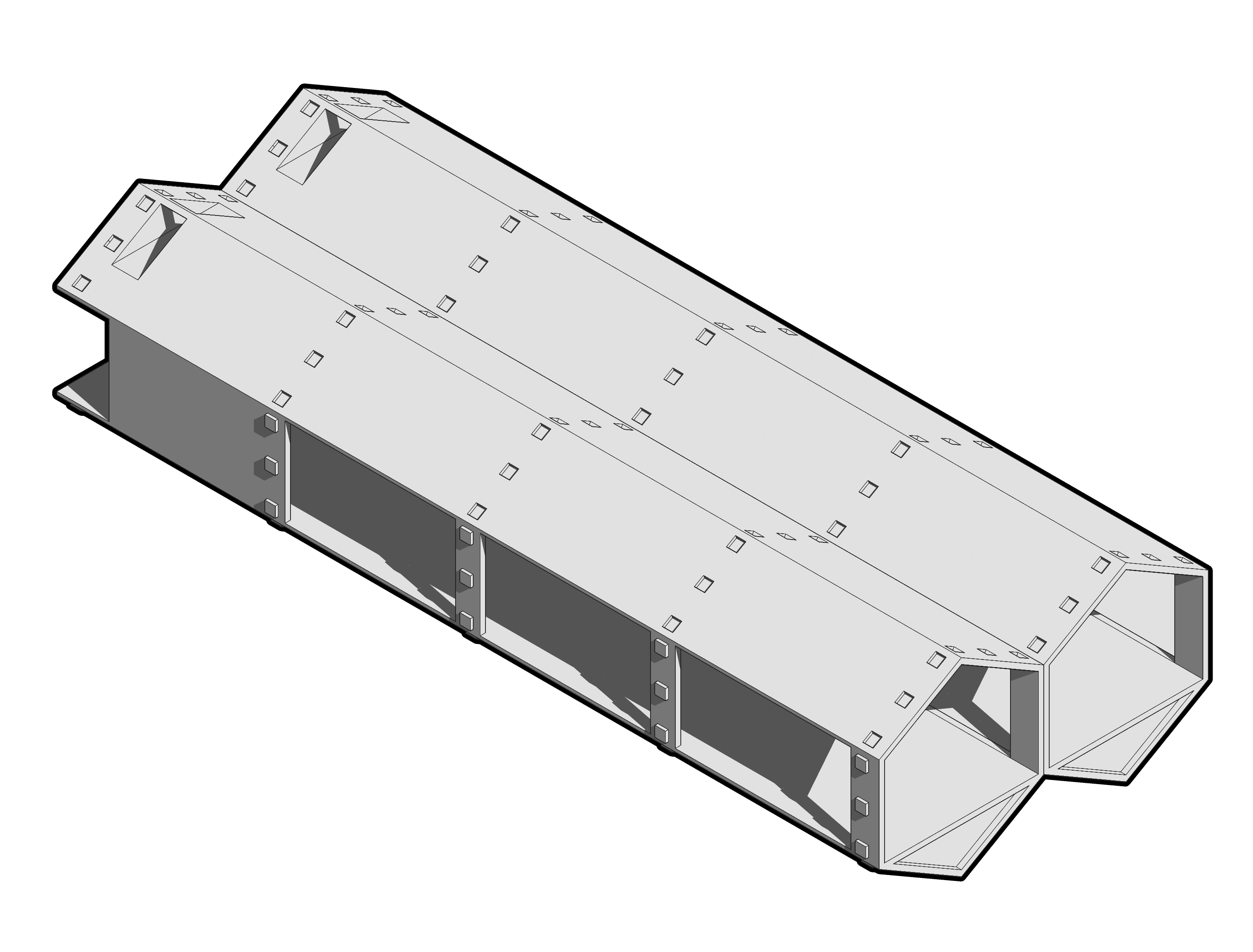

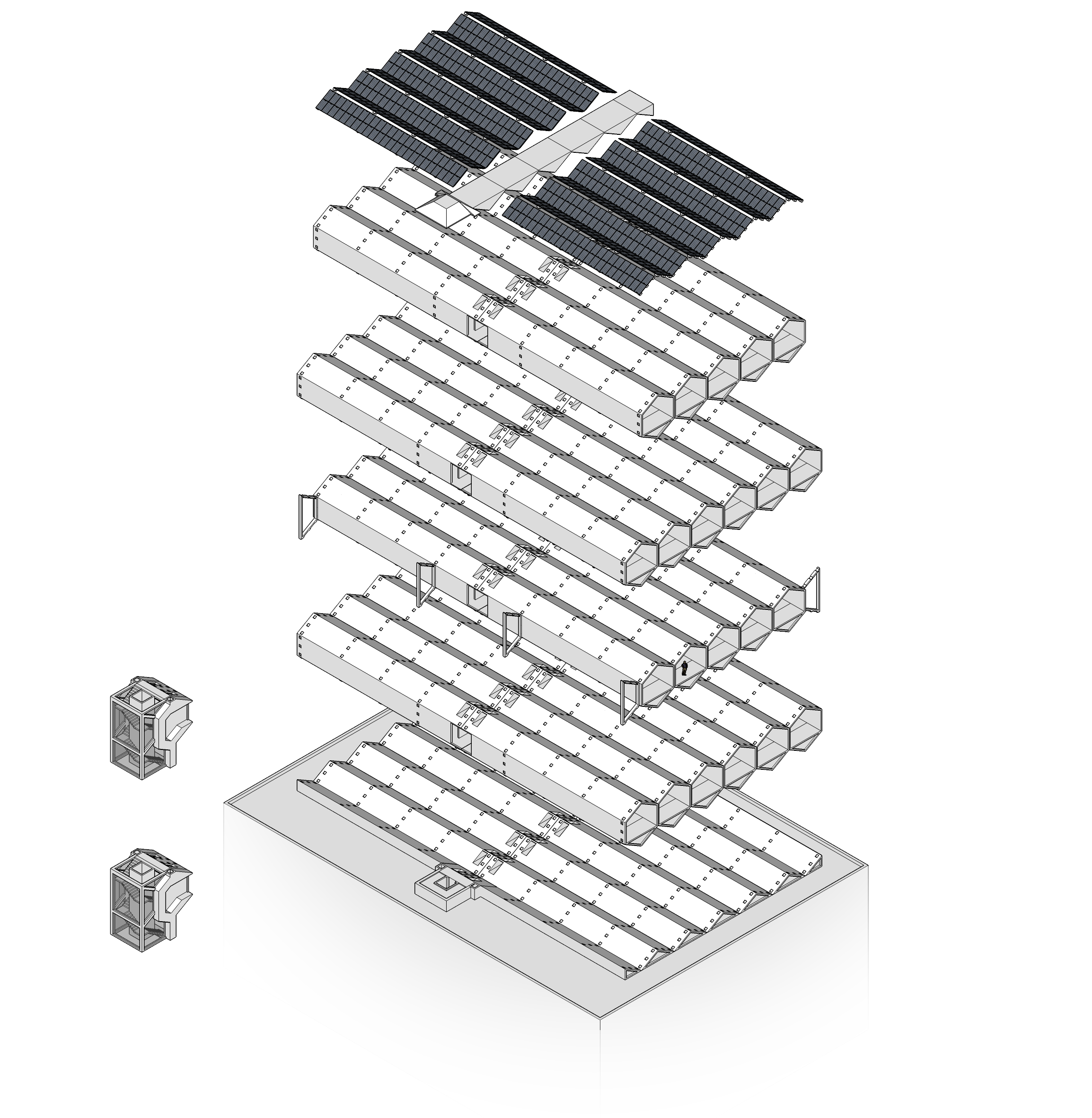

This proposed modular construction system would employ the latest in large scale 3D printing to create a Uni-body or ‘Monocoque’ construction where the ribbing, stud work and external skin are all one continuous piece. This, along with the hexagonal prism shape, would enable superior strength and quick on-site installation of each module. This system would use a 3D printing process that utilises Carbon Fibre, the technology for which has only emerged in that past few years.

It is estimated that only a quarter of all low/medium rise buildings world-wide can support extra floors using traditional steel and concrete methods. This requires the use of lighter materials to create more space, materials such as engineered timbers are prime candidates. However, this proposal would use carbon fibre as it is a material that has a higher strength to weight ratio than steel, concrete, and even LVL or Glulam engineered timbers. It is hoped that this move would enable more buildings around the world to receive vertical extensions and act as permanent carbon sequesters from the use of this fibre.

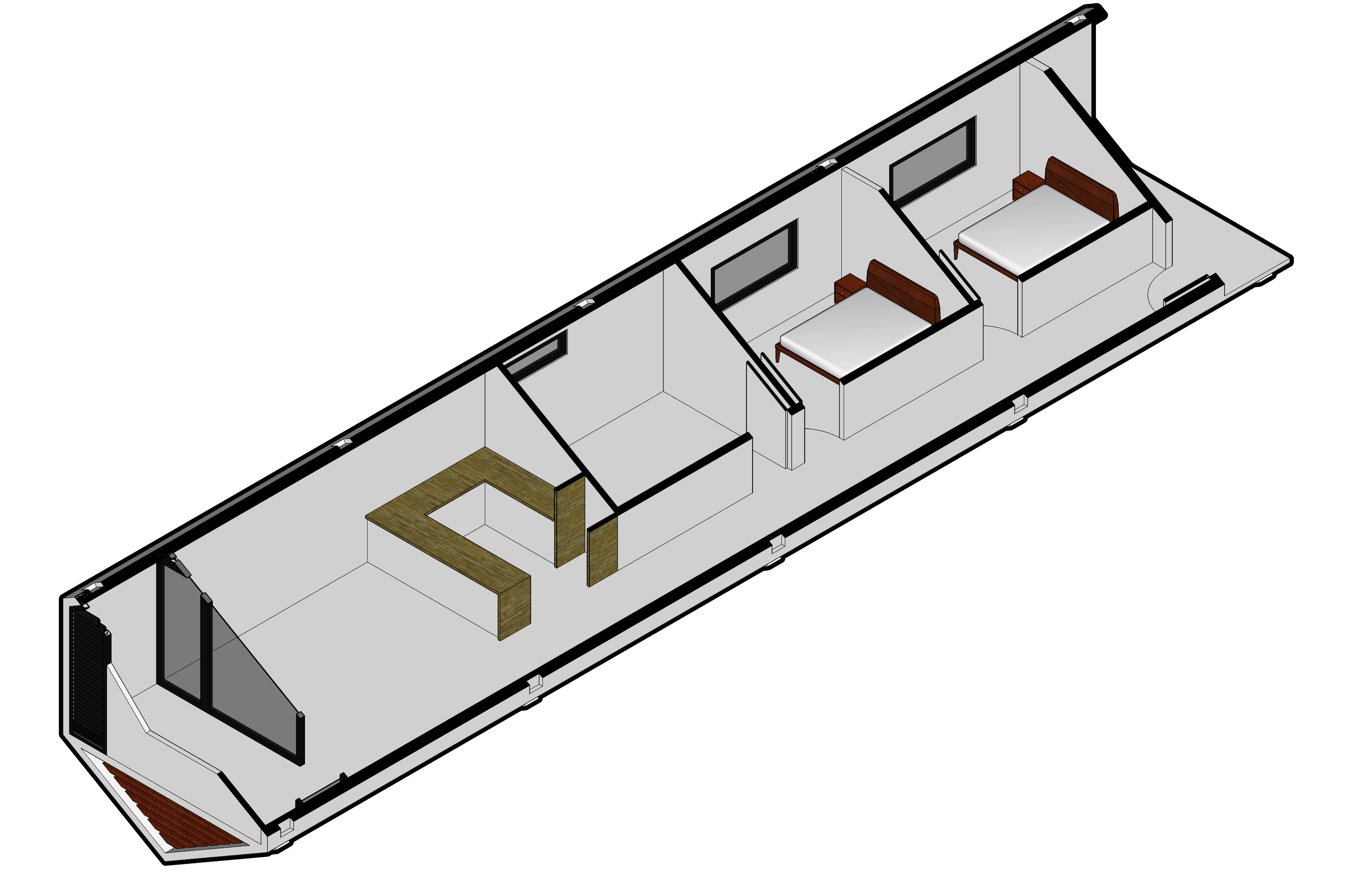

The modular design of this system would be highly adaptable and customisable to client needs, from what kind of finishes apartments would receive, their layout, to office spaces being created by the addition of large gaps in the vertical sides of each module during the printing process. There could also be applications in disaster relief and humanitarian relief scenarios.

There are some challenges that this design would need to overcome. Firstly, though it has become much more accessible in recent years, carbon fibre is still expensive to manufacture with (especially at such large scales).

Secondly, like steel, carbon fibre is electrically conductive which can be extremely dangerous if not managed properly.

Thirdly, if any damage was to be inflicted upon the monocoque structure of a module, repairing this damage would be extremely difficult and could require the complete replacement of the damaged module. It would not be as simple as removing and replacing damaged timber planks, boards, or framing.

Click below to download and view the final presentation material for this project: